The Fredericks Company is an industry leader in electrolytic tilt sensors for an innovative and proven method of measuring anywhere from ±60° down to ±0.5° with high accuracy ranging from ±0.1°

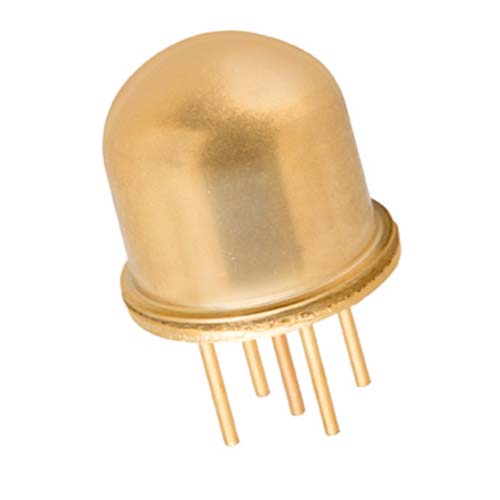

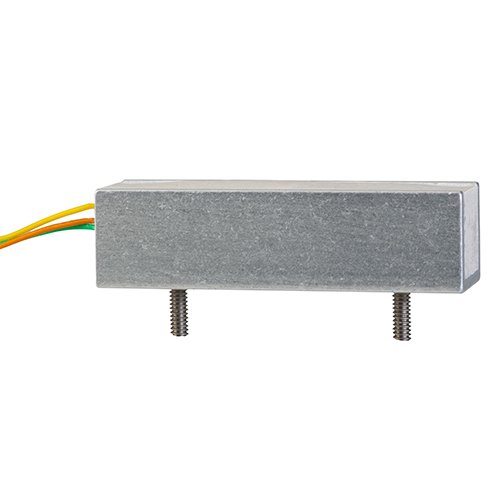

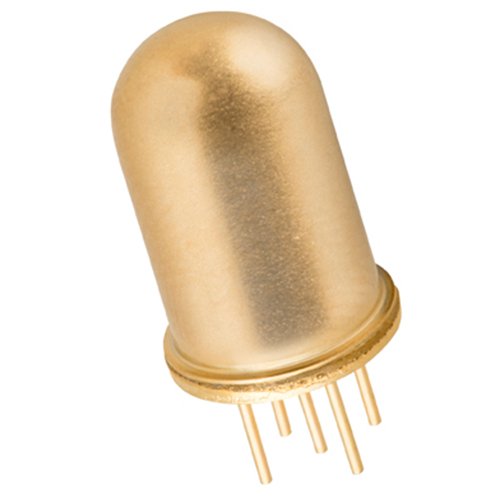

Wide Range Tilt Sensors

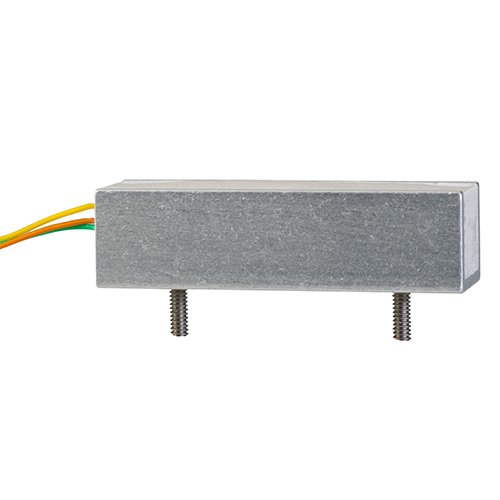

These electrolytic tilt sensors are designed to give wide range measurement up to ±60° with high accuracy from ±0.1° to ±0.05° in one or two axes. They're also the lowest

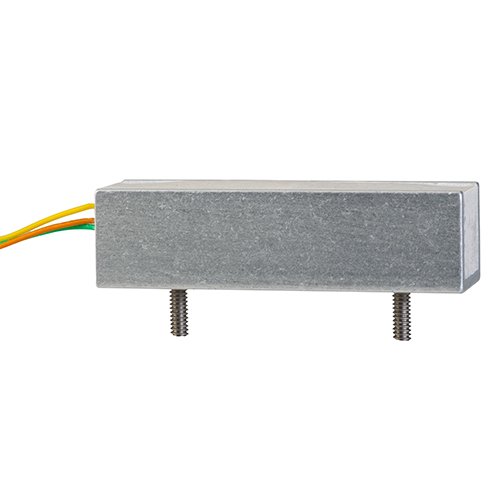

... Read MoreMid-Range Tilt Sensors

These electrolytic tilt sensors are designed to give mid-range measurement up to ±25° with very high accuracy of at least ±0.005° in one axis. This means you’ll need two sensors

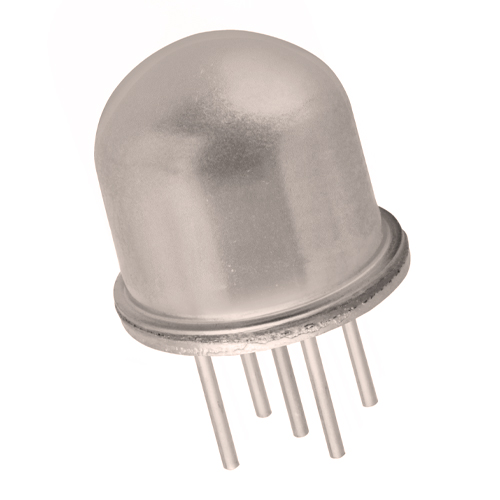

... Read MoreNarrow Range Tilt Sensors

These electrolytic tilt sensors are designed to give narrow range measurement up to ±3° with very high accuracy of at least ±0.001° in one axis. This means that you’ll need

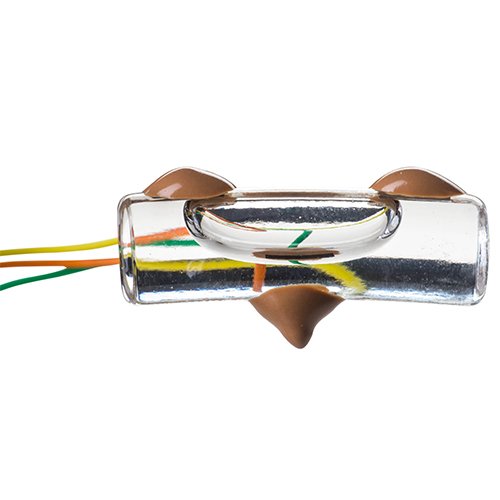

... Read MoreGlass Mid-Range

These electrolytic tilt sensors offer mid-range measurement of ±10° with extremely high accuracy of at least ±0.0005° in one axis. This means you’ll need two sensors to measure in two

... Read MoreGlass Narrow Range

These electrolytic tilt sensors are have narrow range measurement from ±3° to ±0.5° with extremely high accuracy of ±0.0008° to ±0.0001° in one axis. This means you’ll need two sensors

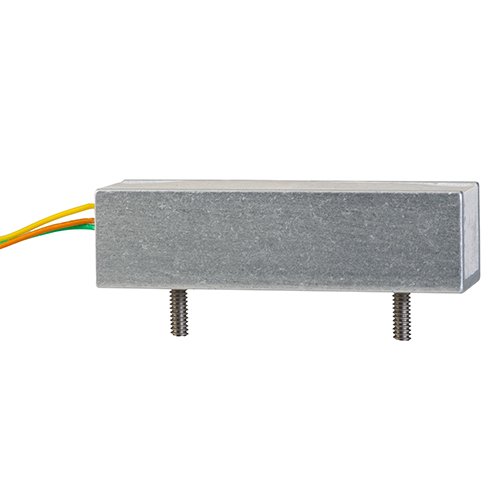

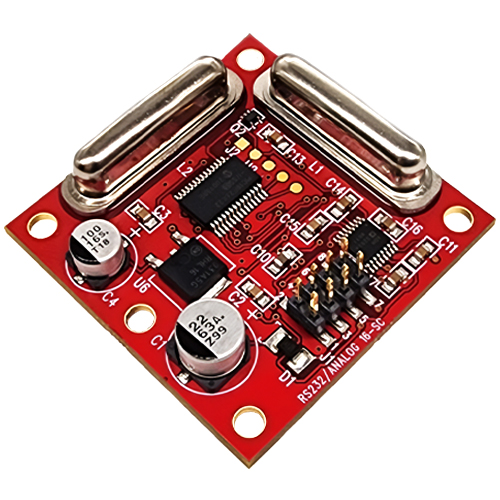

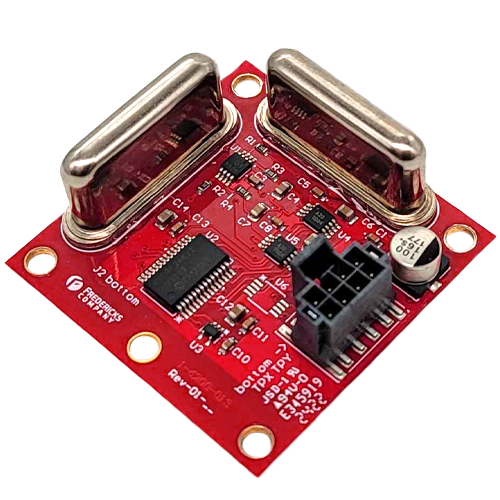

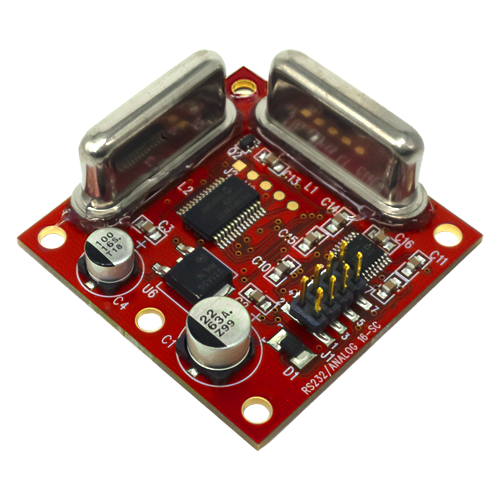

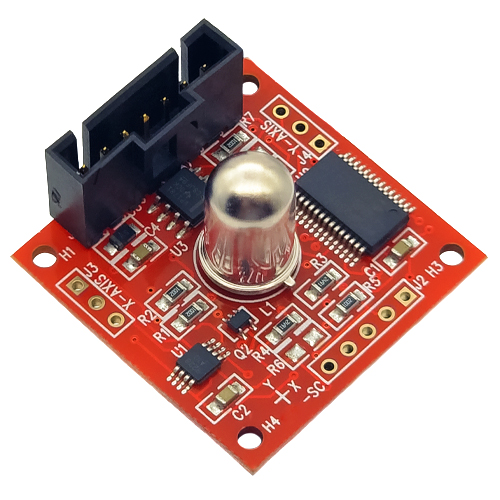

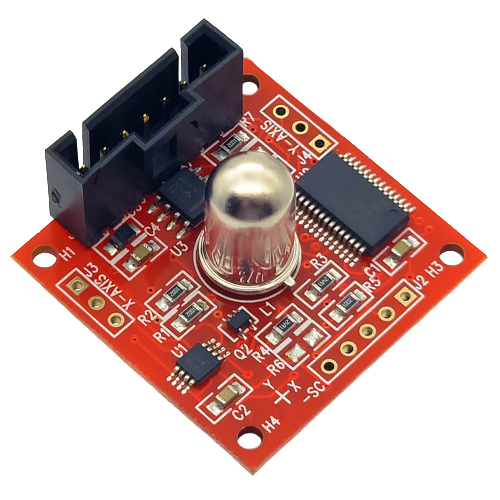

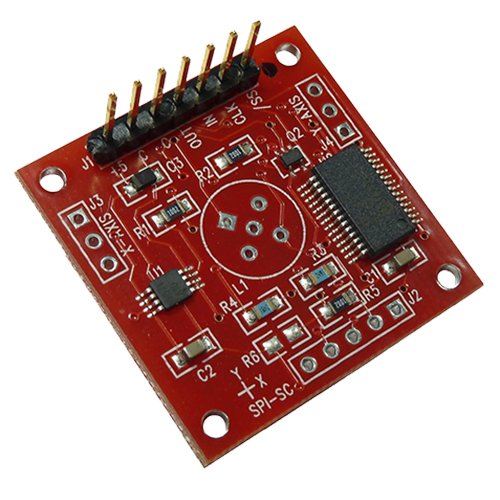

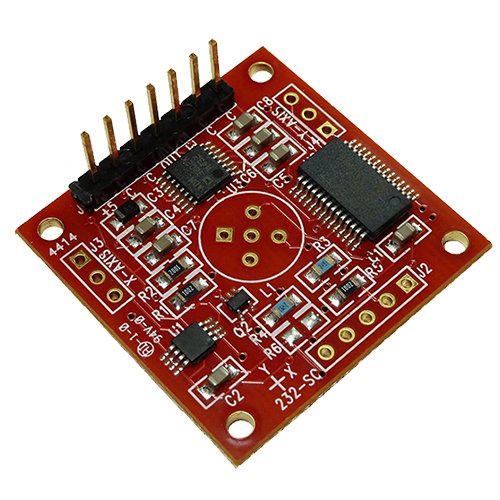

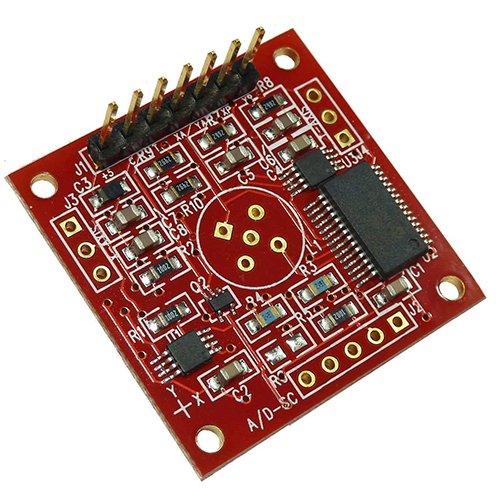

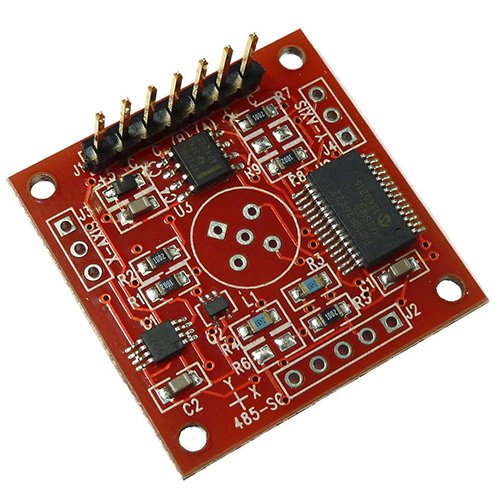

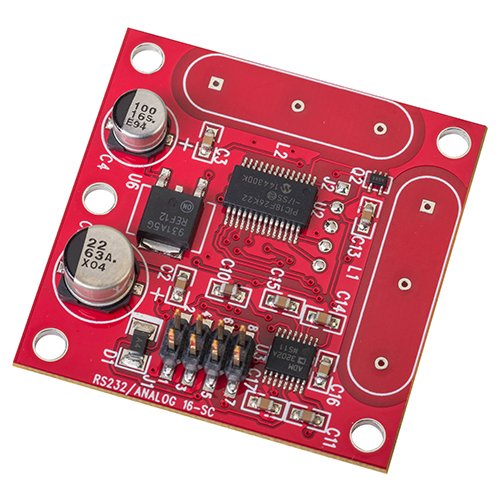

... Read MoreSignal Conditioners - Electrolytic Tilt Sensor Circuits

Electrolytic tilt sensors require a basic electrolytic tilt sensor circuit to generate a tilt angle output. These are often called signal conditioners, signal conditioning boards, or electronic tilt sensors. In ...

Read More

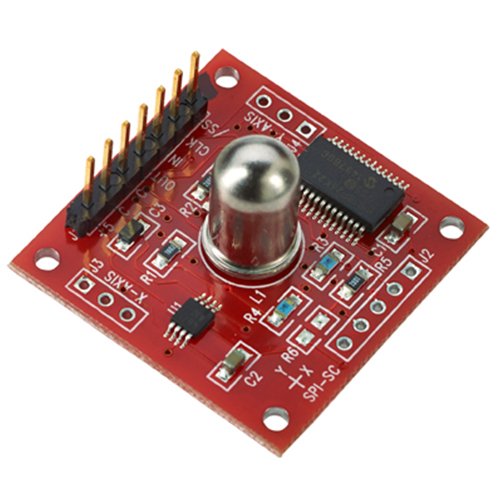

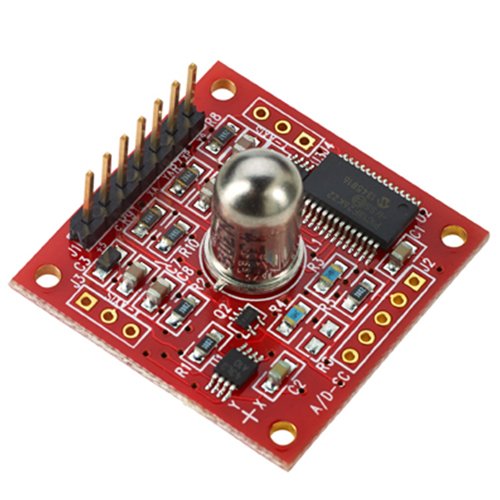

Electrolytic Inclinometer Sensors

The electrolytic versions of our analog and digital inclinometer sensors utilize our Fredericks electrolytic tilt sensors and electrolytic tilt sensor circuits are the lowest cost environmentally sealed (up to IP67)

... Read MoreTilt Switches

Our tilt switches (also referred to as a safety switch or tilt switch sensor module) are very similar to our inclinometers, but instead of a continuous output, tilt switches have ...

Read More