Laser levels and construction tools, in general, are used for a variety of purposes in construction and surveying. Laser levels specifically are used to, you guessed it, make sure things are level, or off-level at a specific angle or grade. This could mean something as simple as hanging a picture in your home, or more complex and impactful like paving a road to a specific grade or making sure the floor of a building is flat. There are several types of laser levels including rotary lasers and line lasers, among others.

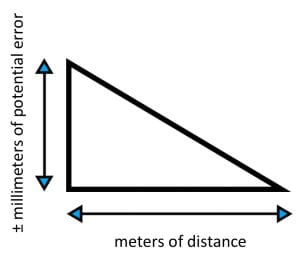

Think about driving your car in the rain; would you prefer that the road has water pooled on it so that you hydroplane, or would you prefer that the road is at an angle so that the water runs off to one side or the other, making for a safer drive to your destination? Laser levels typically have an accuracy defined in ± mm/m or millimeters per meter, which means the potential vertical error in mm for every meter of distance, or:

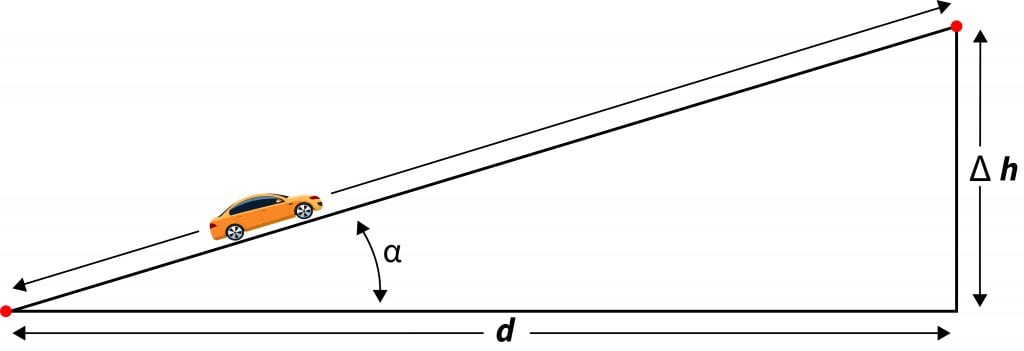

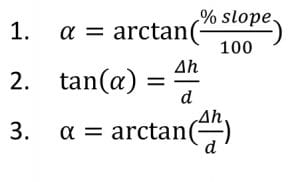

Interested in understanding a % grade vs an angle in degrees? There are a variety of conversions you can do when you know the % grade (or slope), the angle of the slope (see α), or the rise (see Δh) and run (see d):

Here are some other areas where a laser level might be used:

Drop ceiling, cabinet, and shelving installation, construction site layout, land elevations (for construction and agricultural irrigation), fence, post, deck, and masonry alignment.

Note that laser levels typically use very high accuracy tilt sensors in order to maintain precise measurements over long distances. Typical Fredericks sensors for these applications are the 0703-1602-99 for ±25° measurement with ±0.005° repeatability and the 0703-0711-99 for ±3° measurement with ±0.001° repeatability. Both of these are single-axis solutions, but two sensors can be mounted perpendicular for dual (2) axis measurement. As an example, let’s convert these repeatability specifications into mm/m measurements using the equations we talked about before:

This can also be compared with our wide range of tilt sensor solutions, which are a less accurate option but provide 2-axis measurement in a lower-cost package. For example, the 0717-4313-99 tilt sensor has a measurement range of ±50° with ±0.05° repeatability, which converts to the following accuracy in mm/m:

![]()

Note that these repeatabilities (also called accuracy) specifications typically can’t be achieved with low-cost MEMS solutions, or any other low-cost tilt measurement solutions, making electrolytic tilt sensors ideal for this application. Additionally, electrolytic tilt sensors have no moving parts so they don’t have any measurement properties that change over time or temperature. This means that they’re much more repeatable over time and temperature than other solutions.

Recommended Tilt Sensors for Construction Tools and Laser Leveling Equipment

Operating Range: ±25°

Repeatability: ±0.005°

Operating Range: ±25°

Repeatability: ±0.005°

Operating Range: ±3°

Repeatability: ±0.001°

Operating Range: ±50°

Repeatability: ±0.05°

Operating Range: ±25°

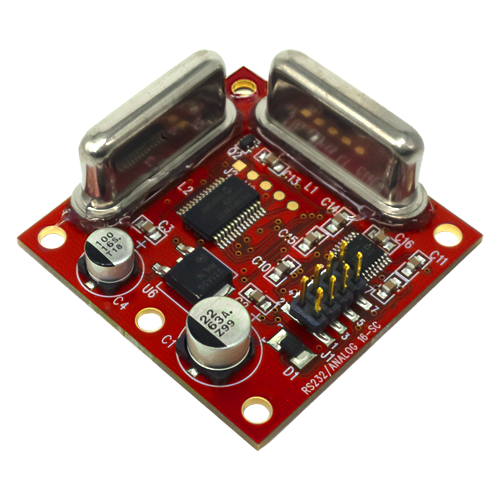

Interface: Analog and RS-232

Operating Range: ±25°

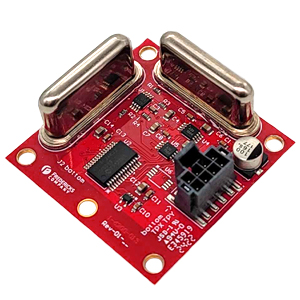

Interface: UART/TTL

Operating Range: ±3°

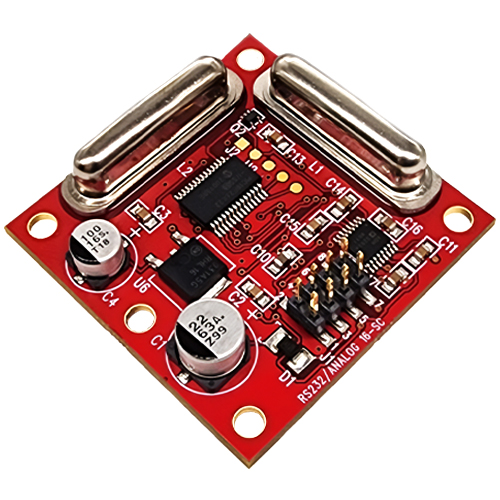

Interface: Analog and RS-232

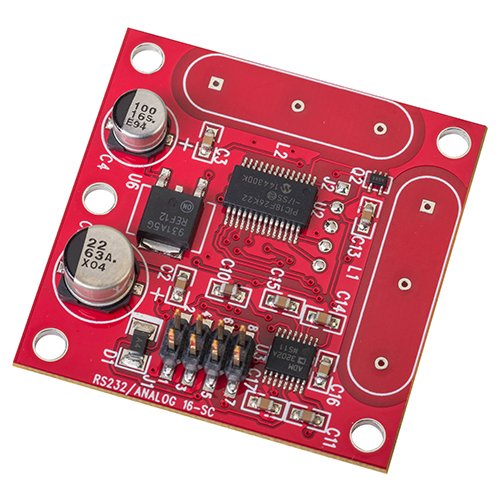

1-6200-XXX Signal Conditioners

Operating Range: 0% to 100% sensor operating range

Supply Voltage: 3.3 V DC to 5 V DC