Railway Monitoring & Rail Accident Prevention

Railways are a critical mode of transportation for both people and goods. As such, it is important to ensure that railway tracks are in good condition to prevent accidents and delays. One of the best ways to monitor the condition of railway tracks is through the use of tilt sensors.

What is an Electrolytic Tilt Sensor?

An electrolytic tilt sensor is a type of angle measurement sensor that uses a conductive fluid to measure tilt. Electrically isolated electrodes (or pins) extend into the fluid and voltage is applied across them. As the sensor position changes, the fluid height at each pin changes, which changes the resistance between each pin. The resistance change can be measured as a voltage change at each pin, which can then be translated into an angle measurement.

The Ideal Solutions

The most common electrolytic tilt sensor for railway monitoring is our 0703-1602-99 single-axis mid-range tilt sensor. This sensor has a measurement range of ±25° with high accuracy measurements with ±0.005° repeatability. The 0703-1602-99 is industrial-grade with a metal construction that can withstand the most extreme environments.

Another electrolytic tilt sensor recommended for railway monitoring is our 0703-0711-99 single-axis narrow-range tilt sensor. This sensor has a measurement range of ±3° with even higher accuracy measurements with ±0.001° repeatability. The 0703-0711-99 is also industrial-grade with a metal construction that’s designed to withstand the most extreme environments.

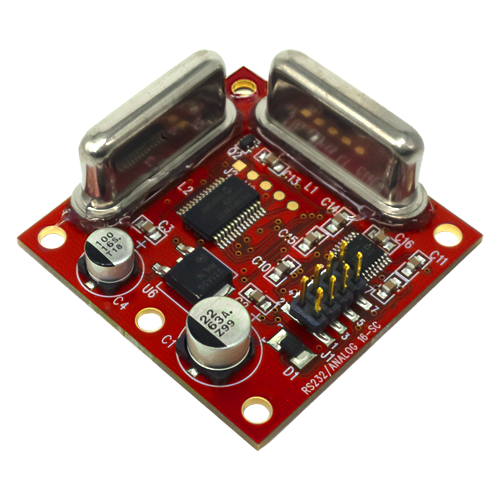

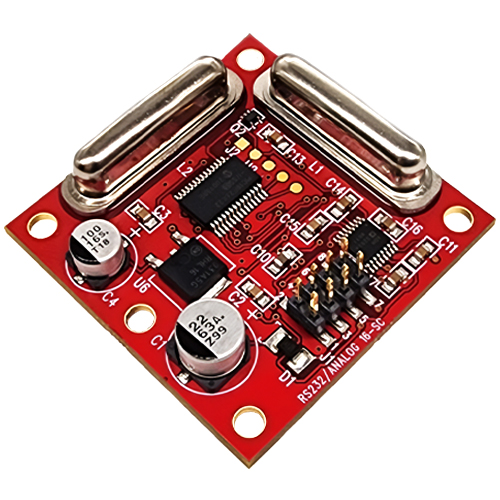

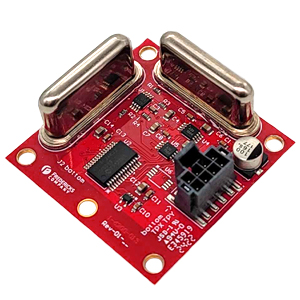

Electrolytic tilt sensors require a control circuit which we offer as a packaged solution which we call an inclinometer. Our electrolytic tilt sensing technology makes these inclinometers extremely stable with no long-term drift compared to MEMS inclinometers, all in a package that’s simple to integrate.

Advantages of Electrolytic Tilt Sensors for Railway Monitoring

- Accuracy

- Reliability

- Improved Safety

- No Drift

- Low Power Consumption

- Easy to Integrate

- Cost-Effective

Applications of Electrolytic Tilt Sensors in Railway Monitoring

- Track Monitoring

- Train Monitoring

- Bridge and General Structural Monitoring

Additional Resources

- AN 1000: Electrolytic Tilt Sensor Excitation

- AN 1001: Temperature Compensation of Electrolytic Tilt Sensors

- AN 1005: Converting Tilt Angle to Degrees

- AN 1006: Obtaining Measurements from TFC Signal Conditioners

- 3D Models (STEP Files)

- Development Tools

- Angle Measurement Converter

- Video: What is an Electrolytic Tilt Sensor?