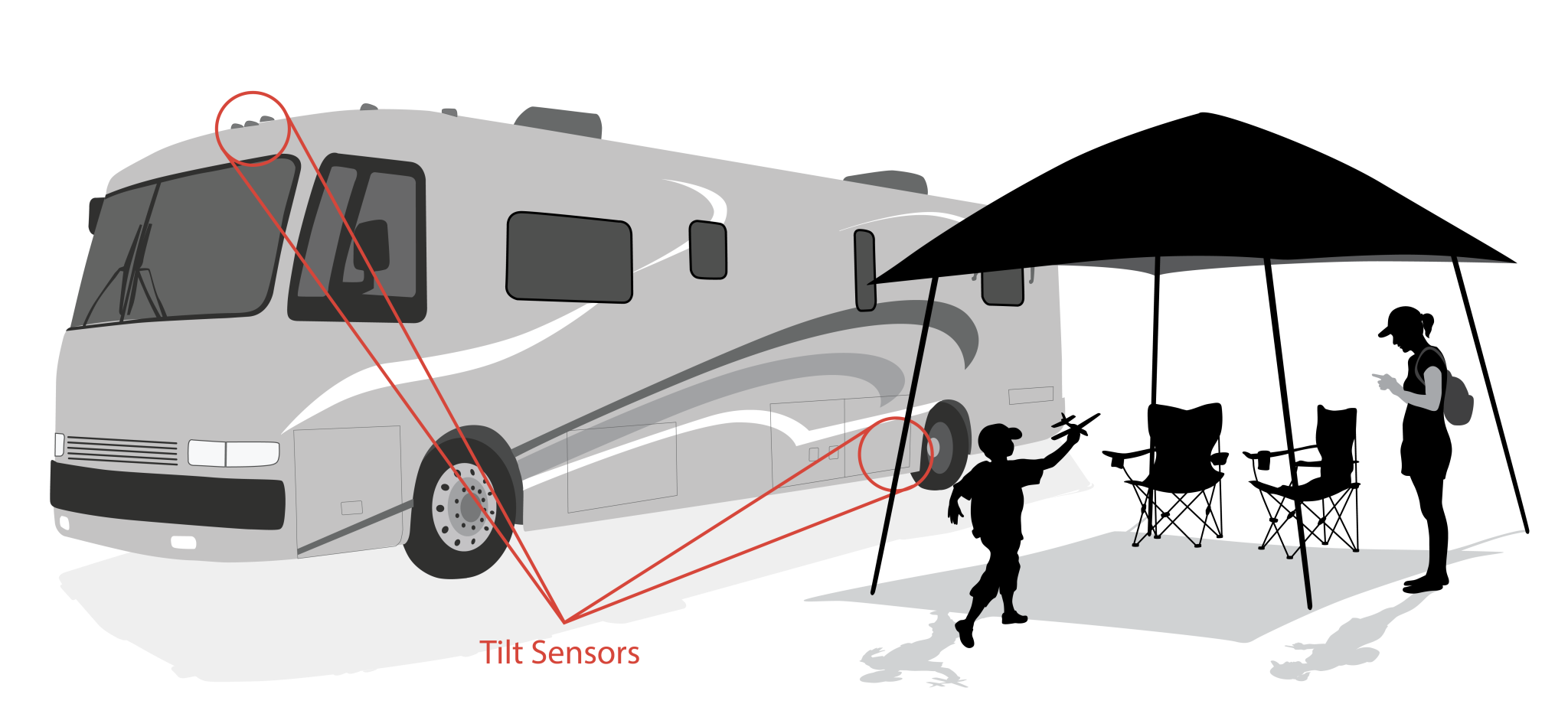

Uneven ground can be problematic for RVs and other large vehicles when they’re parked, not only for your comfort but also for the functionality of appliances and systems. To resolve this, a hydraulic and electric RV leveling system or RV leveler is used to quickly, accurately, and automatically level and stabilize an RV parked on uneven ground with the touch of a button. Auto RV leveling systems and RV levelers are more efficient and effective than using multiple manual jacks, or traditional, inaccurate bubble levels. What’s at the heart of an RV leveling system? A tilt sensor.

Why Electrolytic Tilt Sensors for an RV Leveling System?

There are many different types of tilt sensors, but electrolytic tilt sensors are the most common for an RV leveler. There are four primary reasons for this:

- Accuracy and repeatability

- Long term stability and turn on bias

- Temperature stability

- Cost

The two most common products for the RV leveler market are our 0717-4319-99 and 0717-4313-99 dual-axis tilt sensors. Their wide operating range of ±50° tilt removes any concerns related to mounting and significantly simplifies manufacturing, testing, and installation in an RV leveler for an OEM or end-user. Compared to other tilt sensing technology available at the same price, these two tilt sensors provide much better accuracy, down to a tenth of a degree (±0.1°) for the 0717-4319-99 and down to half-a-tenth of a degree (±0.05°) for the 0717-4313-99.

This high accuracy is maintained over the life of the sensor and takes into account any turn-on bias (also called null offset or zero drift), which causes significant error in angle readings with many other tilt sensing technologies, which will cause long-term problems with your RV leveling system. The accuracy is also maintained over a wide temperature range which encompasses anything you might normally experience outside or in the cabin of a vehicle in outdoor conditions, from -40 °C to 85 °C (or -40 °F to 185 °F).

Recommended Tilt Measurement Solutions for RV Leveling Systems

Operating Range: ±60°

Repeatability: ±0.1°

Operating Range: ±50°

Repeatability: ±0.05°