Fournir la solution de surveillance sans fil la plus efficace au monde sur le plan énergétique grâce aux capteurs d'inclinaison électrolytique de Fredericks

Introduction

There are over 612,000 bridges in the United States and as of February 2017, almost 10% of them need to be repaired or replaced according to The American Road and Transportation Builders Association. That means that there are currently over 55,000 bridges that require real-time monitoring in order to avoid a catastrophe like the 2007 bridge collapse in Minneapolis, Minnesota.

Qu'est-ce que Resensys ?

Resensys propose des solutions rentables et évolutives pour aider à évaluer la stabilité structurelle de ces ponts et d'autres ponts autoroutiers, afin de mettre en évidence les problèmes structurels et de planifier l'entretien et les réparations nécessaires pour assurer la sécurité et la longévité des ponts.

Leur solution de surveillance sans fil de la santé des structures, SenSpot™, est destinée aux ponts existants et aux ponts en construction. Elle comprend des capteurs sans fil de petite taille, peu coûteux et faciles à installer, qui mesurent diverses variables affectant la performance d'un pont.

Né des recherches menées par le président et directeur technique Mehdi Khandani à l'université du Maryland, Resensys est un leader dans la surveillance géostructurelle en temps réel et offre le système de surveillance de pont sans fil le plus durable avec une durée de vie minimale prévue de 10 ans. Pour plus d'informations, visitez le site http://www.resensys.com.

Le défi

Bien qu'il existe d'autres capteurs sur le marché pour la surveillance des infrastructures, ce qui différencie un appareil Resensys est sa très faible consommation d'énergie, qui n'utilise que 4 microwatts environ, soit environ 100 millions de fois moins qu'une ampoule ordinaire. Cela signifie qu'un capteur SenSpot a une durée de vie minimale de 10 ans en utilisant seulement une petite batterie ½-AA.

Afin d'offrir un système de surveillance aussi efficace et précis, Resensys devait trouver un capteur d'inclinaison avec une résolution allant jusqu'à un millième de degré tout en offrant une faible consommation d'énergie, une durabilité et une durée de vie d'au moins 10 ans.

La solution

Dr. Khandani and his team thoroughly evaluated a variety of MEMS and other electrolytic tilt sensors and concluded that the Fredericks Single-Axis Narrow-Range Electrolytic Tilt Sensor (PN 0703-0711-99) significantly outperformed competing products in terms of long term repeatability and resolution.

“Qualitatively, Fredericks’ devices were an order of magnitude better than both MEMS and competing electrolytic sensors,” says Dr. Khandani. “In our application, repeatability is very important and none of the competing products did as great as Fredericks products did.”

Les résultats

With the help of Fredericks’ electrolytic tilt sensors, Resensys is able to offer the world’s most energy-efficient wireless monitoring solution that helps keep travelers safe with around 5,000 SenSpot™ tilt units in use in the US and around the world.

“Our decision to use Fredericks products was driven by the excellent accuracy and durability of their tilt sensors,” Dr. Khandani adds. “Such long term and high-quality measurements help capture the smallest movement and instability on critical bridge components.”

SenSpot™ en action : Pont de la rivière Patapsco

In the Spring of 2014, cracks were spotted in the girders and piers of the I-70 Patapsco River Bridge near Baltimore, Maryland. Engineers found that non-responsive bearings had caused damage to piers and steel girders of the bridge, which led to its closure in June 2014.

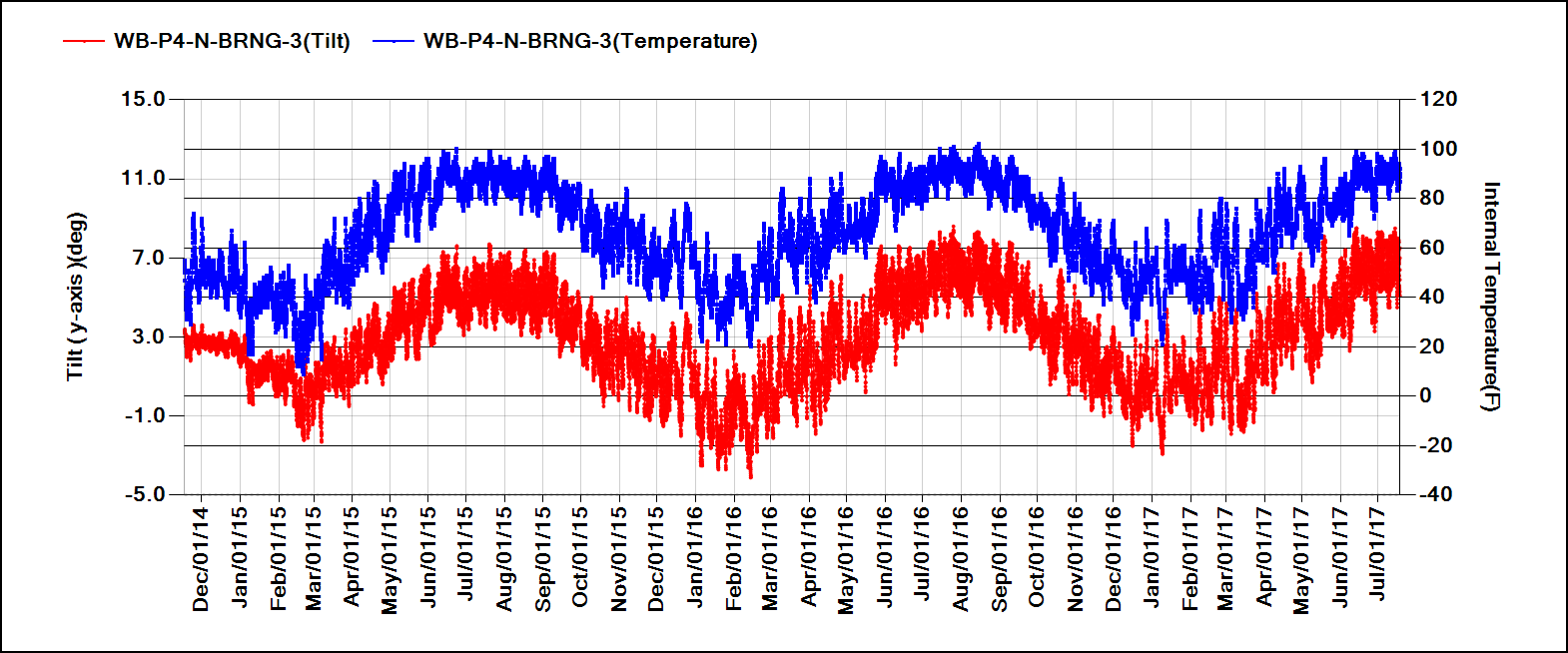

Repairs were made, retrofits were applied, and a SenSpot™ monitoring system was installed in July 2014 to detect any further changes. More than 40 SenSpot™ units were mounted on the bridge, including 12 tilt sensors located on the bridge’s rocker bearings to monitor the movement pattern and detect non-responsiveness or over-responsiveness. In addition, six high-resolution tilt sensors were mounted on the bridge’s piers to monitor the deflection and rotation of the bridge rocker bearings caused by cold temperatures.

Early results from August to November 2014 found that the bearings on two piers were non-responsive to temperature changes and an additional bearing saw only 20% of expected movement. Data collected through Spring 2015, however, showed that the bearings had an unprecedented response to the robust retrofits (combined with especially cold winter), and by March 2015 all piers and respective bearings were fully responsive.

Dr. Khandani notes, “After more than four years of continuous monitoring, we are pleased that the Fredericks devices used in SenSpot™ sensors produce very consistent, repeatable, and high-quality measurements of tilt and inclination at sub-arc-second resolution.”

Before alerting the Maryland State Highway Administration, the Resensys team worked with engineers at Fredericks to confirm the data. At Fredericks, we take a partnership approach to our relationships with customers, and customer satisfaction is a priority. We have dedicated representatives and engineers committed to providing highly responsive service, and our customers have anytime-access to our leadership team, made possible in part by our “not too big, not too small” operation.