Fornire la soluzione di monitoraggio wireless più efficiente al mondo in termini energetici con l'aiuto dei sensori elettrolitici di inclinazione di Fredericks

Introduzione

Negli Stati Uniti ci sono oltre 612.000 ponti e, a febbraio 2017, quasi il 10% di essi deve essere riparato o sostituito, secondo l'American Road and Transportation Builders Association. Ciò significa che attualmente ci sono più di 55.000 ponti che richiedono un monitoraggio in tempo reale per evitare una catastrofe come il crollo del ponte del 2007 a Minneapolis, Minnesota.

Che cos'è Resensys?

Resensys offre soluzioni economiche e scalabili per aiutare a valutare la stabilità strutturale di questi e di altri ponti autostradali in modo da individuare i problemi strutturali e pianificare la manutenzione e le riparazioni necessarie per garantire la sicurezza e la longevità del ponte.

La loro soluzione wireless per il monitoraggio strutturale della salute, SenSpot™, è per ponti esistenti e ponti in costruzione ed è dotata di sensori wireless piccoli, economici e facili da installare che misurano una varietà di variabili che influenzano le prestazioni di un ponte.

Nato dalla ricerca condotta dal Presidente e CTO Dr. Mehdi Khandani dell'Università del Maryland, Resensys è leader nel monitoraggio geostrutturale in tempo reale e offre il più durevole sistema di monitoraggio dei ponti wireless con una durata minima prevista di 10 anni. Per maggiori informazioni visitate il sito http://www.resensys.com.

La sfida

Anche se esistono altri sensori sul mercato per il monitoraggio delle infrastrutture, ciò che differenzia un dispositivo Resensys è il suo bassissimo consumo energetico, che utilizza solo circa 4 microwatt, o circa 100 milioni di volte meno di una tipica lampadina. Questo significa che un sensore SenSpot ha una durata minima di 10 anni utilizzando solo una piccola batteria da ½-AA.

Per offrire un sistema di monitoraggio così efficiente e preciso, Resensys aveva bisogno di trovare un sensore di inclinazione con una risoluzione fino a un millesimo di grado, offrendo al tempo stesso un basso consumo energetico, una lunga durata e una durata del prodotto di almeno 10 anni.

La soluzione

Il dott. Khandani e il suo team hanno valutato a fondo una serie di sensori di inclinazione elettrolitici MEMS e di altro tipo e hanno concluso che il sensore di inclinazione elettrolitico Fredericks ad asse singolo a gamma ristretta (PN 0703-0711-99) ha superato in modo significativo i prodotti concorrenti in termini di ripetibilità e risoluzione a lungo termine.

"Dal punto di vista qualitativo, i dispositivi Fredericks sono risultati di un ordine di grandezza superiore sia ai MEMS che ai sensori elettrolitici della concorrenza", afferma il dott. "Nella nostra applicazione, la ripetibilità è molto importante e nessuno dei prodotti concorrenti è riuscito a fare altrettanto bene dei prodotti Fredericks".

I risultati

Con l'aiuto dei sensori elettrolitici di inclinazione di Fredericks, Resensys è in grado di offrire la soluzione di monitoraggio wireless più efficiente al mondo, che aiuta a mantenere i viaggiatori al sicuro con circa 5.000 unità di inclinazione SenSpot™ in uso negli Stati Uniti e in tutto il mondo.

"La nostra decisione di utilizzare i prodotti Fredericks è stata dettata dall'eccellente accuratezza e durata dei loro sensori di inclinazione", aggiunge il Dr. Khandani. "Queste misure di lunga durata e di alta qualità aiutano a catturare i più piccoli movimenti e instabilità dei componenti critici del ponte".

SenSpot™ in azione: Ponte sul fiume Patapsco

Nella primavera del 2014 sono state riscontrate delle crepe nelle travi e nei pilastri del ponte sul fiume Patapsco della I-70 vicino a Baltimora, nel Maryland. Gli ingegneri hanno scoperto che i cuscinetti non rispondenti avevano causato danni alle pile e alle travi in acciaio del ponte, che hanno portato alla sua chiusura nel giugno 2014.

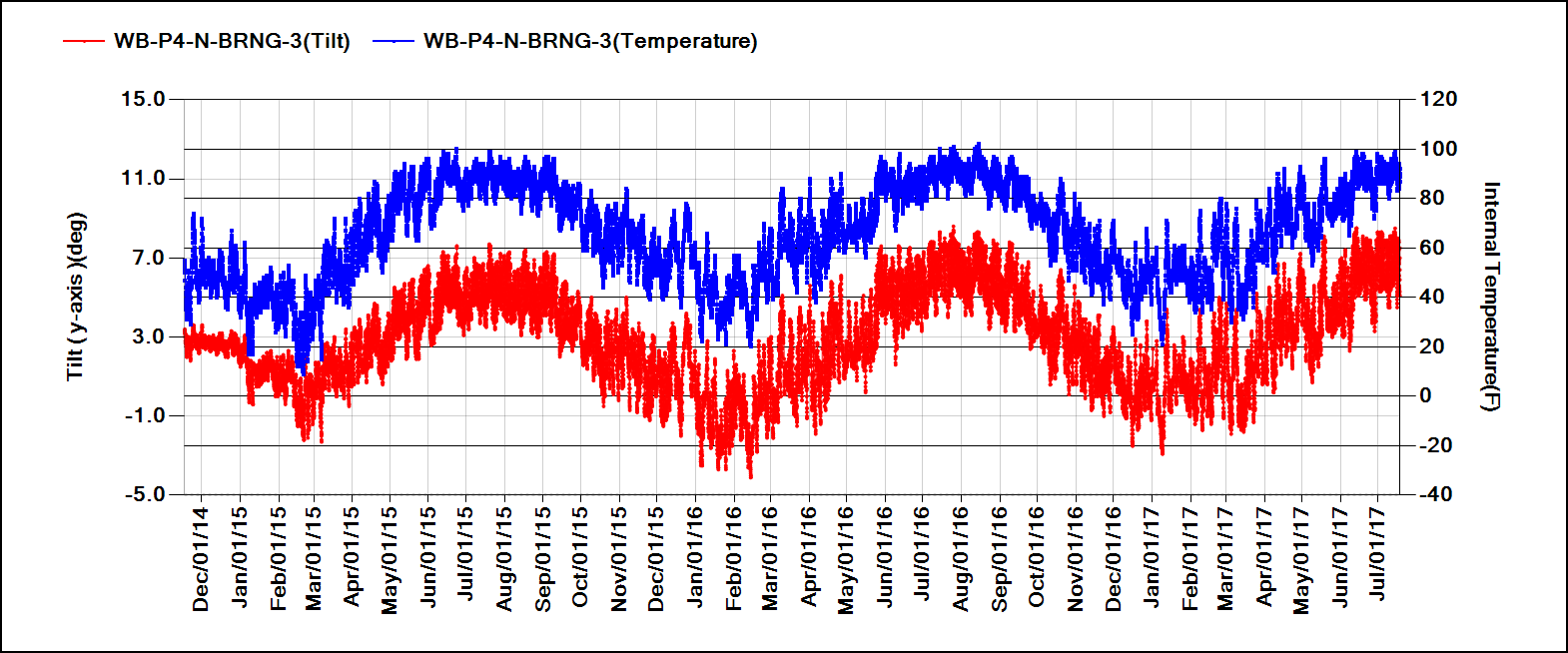

Le riparazioni sono state effettuate, sono stati applicati dei retrofit e nel luglio 2014 è stato installato un sistema di monitoraggio SenSpot™ per rilevare eventuali ulteriori cambiamenti. Sul ponte sono state montate più di 40 unità SenSpot™, tra cui 12 sensori di inclinazione posizionati sui cuscinetti del ponte per monitorare il modello di movimento e rilevare la mancata o eccessiva reattività. Inoltre, sei sensori di inclinazione ad alta risoluzione sono stati montati sui piloni del ponte per monitorare la deflessione e la rotazione dei cuscinetti del ponte causati dalle basse temperature.

I primi risultati, da agosto a novembre 2014, hanno rilevato che i cuscinetti di due moli non rispondevano alle variazioni di temperatura e un altro cuscinetto ha registrato solo il 20% del movimento previsto. I dati raccolti nella primavera del 2015, tuttavia, hanno mostrato che i cuscinetti hanno avuto una risposta senza precedenti ai robusti interventi di retrofit (combinati con un inverno particolarmente freddo) e a marzo 2015 tutti i moli e i rispettivi cuscinetti erano completamente reattivi.

Dopo oltre quattro anni di monitoraggio continuo, siamo lieti di constatare che i dispositivi Fredericks utilizzati nei sensori SenSpot™ producono misure di inclinazione e inclinazione molto coerenti, ripetibili e di alta qualità con una risoluzione inferiore al secondo d'arco."

Prima di allertare la Maryland State Highway Administration, il team di Resensys ha collaborato con gli ingegneri di Fredericks per confermare i dati. In Fredericks adottiamo un approccio di partnership nei rapporti con i clienti e la loro soddisfazione è una priorità. Abbiamo rappresentanti e ingegneri dedicati che si impegnano a fornire un servizio altamente reattivo, e i nostri clienti hanno accesso in qualsiasi momento al nostro team di leadership, reso possibile in parte dalla nostra operazione "non troppo grande, non troppo piccola".