7 Reasons to Upgrade from MM200 to MX200

Due to the advent of transistor technology, vacuum controllers have transformed vastly over the years from analog instruments into digital instruments. As technology continues to rapidly evolve, vacuum controllers, such as our MM200 and MX200, continue to advance and improve.

Consider how vacuum controllers have improved by discovering how our MX200 advances the feature set of the MM200.

The MM200 controlled any TELEVAC vacuum sensor including cold cathode, convection, diaphragm, hot ion, and thermocouple sensors. It maintained optional features including up to eight relay set points and RS-232/RS-485 communications. As a modular unit, the system allowed customers to choose a vacuum sensing solution specific to their needs. The distinct benefits of the U.S. made and manufactured MM200 included its customer configurable and rack mountable design, built-in self-diagnostics, easy to read LED display, selectable units of measurements, digital interface, and a single analog output per sensor.

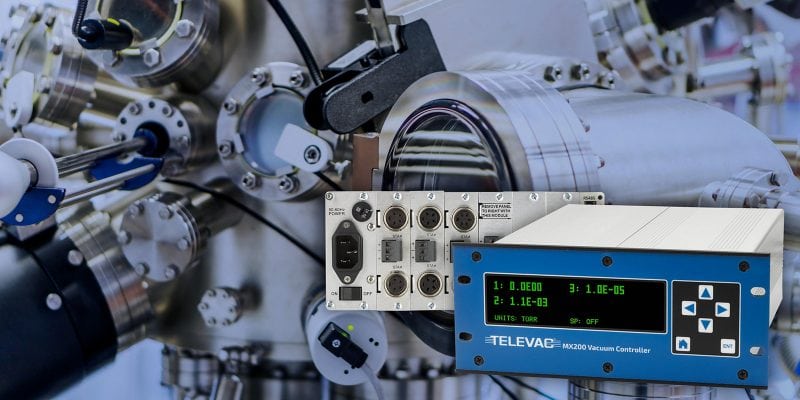

Fredericks recently introduced to the market the MX200 , which includes all of the functions set forth by the MM200, plus:

- Enhanced display capabilities

An auto-scaling feature increases the size of the text as fewer channels are displayed, enabling readings to be seen from further away. The MX200 also includes a unique feature that allows all channels to be turned off on the display. While the MM200 allowed only two channels to be viewed on the front panel, the MX200 allows for up to eight channels to be displayed simultaneously. - Full menu functionality

The MM200 included limited menu functionality, allowing only certain settings to be changed through the front panel. The MX200 has full menu functionality due to its higher resolution display and allows all settings to be accessed through the front panel or by digital communications. - Customizable analog output ranges

The MM200 had preset ranges for the analog outputs that could not be adjusted, while the MX200 has the ability to set the range for the logarithmic and linear analog outputs. The analog outputs are also settable by channel, rather than sensor type, a customization only available on the MX200. - Faster sampling rate

The MX200 has a substantially faster sampling rate of ≤10 milliseconds compared to the MM200 which can be up to 20x slower depending on the number of sensors connected. - Superior sensor accuracy

The MM200 had – at most – two calibration adjustments for each sensor and the calibration was done manually with potentiometers. With the MX200, the calibration is completely digital and includes more calibration points, providing enhanced accuracy over the operating range of each sensor. - Increased configurability

Unlike the MM200 which was limited to RS-232 and RS-485 serial communications as an add-on option, the MX200 has USB, RS-232, and RS-485 included standard with every unit. The USB connection also allows it to be directly connected to a PC instead of through an RS-232/USB or RS-485/USB converter as is required with the MM200 with almost all newer PCs. The addition of USB also allows the user to communicate with the MX200 with a tablet or phone by purchasing a USB OTG cable and downloading a free app. Additionally, the MX200 has built-in correction for 7 gas types that can be configured individually for each channel. The MM200 only supports 2 gas types. - Saves time and money

The MX200 has field upgradable firmware allowing the end user to update the unit without returning it to the factory. This isn’t possible with the MM200, which saves the cost and time of shipping, saving the customer money and decreasing their downtime if an update is required.

In addition to the added features and benefits of the MX200, the sensor control modules of the MM200 can be transferred over or retrofitted. This option is more cost-effective than purchasing a new MX200, as the module costs are not included. Additionally, all sensors and cables are the same and therefore, do not need to be purchased new with an MX200.

For more information on Fredericks or any of our products, contact us today.

If you are interested in guest blogging opportunities, please contact Shawn Orr at 215.938.4422.

Return to Blog