Part Number: 2-7900-037

Compatible With: 1E Piezo Diaphragm, 1F Piezo Diaphragm, 2A Thermocouple, 2A VacuMini, 2A NASA Mini, 4A Convection, 7B Cold Cathode, 7E Cold Cathode, 7F Cold Cathode, 7FC Cold Cathode, 7FCS Cold Cathode, CDG, Set Point Relays

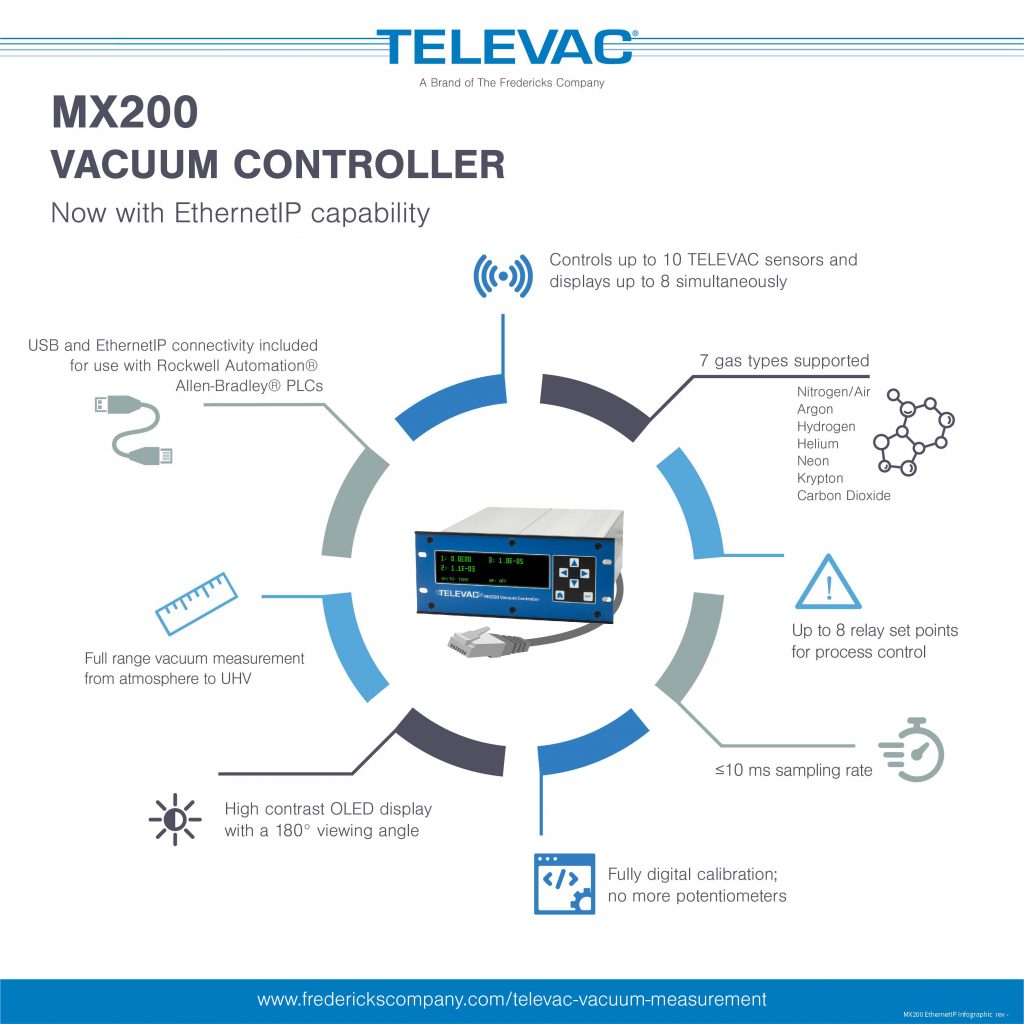

Features and Benefits:

- Rack mountable with a highly configurable design

- USB included in every unit for simple connection with a PC

- High contrast OLED display with 180° viewing angle

- Selectable units of measurement (Torr, mbar, Pascal)

- Bootloader for field upgradeable firmware

- Gas conversion functions included for nitrogen/air, argon, hydrogen, helium, neon, krypton, and carbon dioxide

- Analog outputs (0 to 10 V DC) for every connected passive vacuum gauge

- User-configurable analog output ranges

- Excellent customer support

- ISO 17025 accredited and NIST traceable calibrations optional

- DHCP enable or disable with programmable IP address

- Status LEDs for network/module status/port data activity

- 10/100 Mbit, half or full duplex port operation

- Secure web access for network and unit data and settings

| Instrument | Part Number | |

| MX200 Base Unit EthernetIP/USB | 2-7900-037 | |

| MX200 Base Unit PROFINET/USB | 2-7900-038 | |

| MX200 Base Unit RS-232/RS-485/USB | 2-7900-034 | |

| Module | Part Number | Slot (max) |

| Set Point Quad Relay | 2-6200-411 | 1 (2) |

| 1E Dual Piezo Diaphragm | 2-6200-220 | 1 (5) |

| 1F Dual Piezo Diaphragm | 2-6200-244 | 1 (5) |

| 2A Dual Thermocouple | 2-6200-486 | 1 (5) |

| 4A Dual Convection | 2-6200-415 | 1 (5) |

| 7B Penning Magnetron Cold Cathode | 2-6200-227 | 2 (3) |

| 7EF DI Magnetron Cold Cathode | 2-6200-285 | 1 (5) |

| Capacitance Diaphragm (24 V DC) | 2-6200-451 | 1 (5) |

| Capacitanc Diaphragm (15 V DC) | 2-6200-452 | 1 (5) |

| Operating Range | 1*10-11 Torr to 10,000 Torr |

| Communications | USB/EthernetIP |

| Analog Output | 0 to 10 V DC (1 per sensor) |

| Analog Output Resolution | 16 Bits |

| Programmable Set Points | 4 per module (8 max) |

| Set Point Type | Relay |

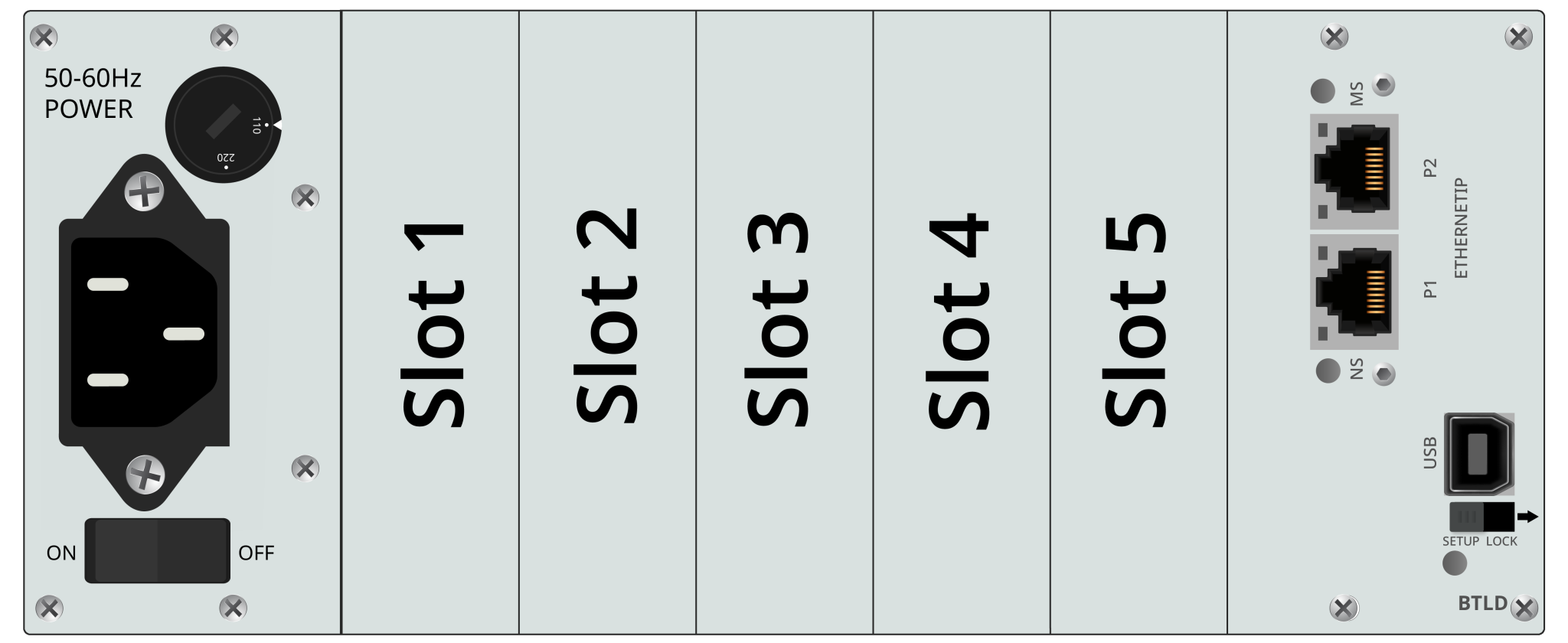

| Supply Voltage | 115/230 V AC (2/1 A), 50-60Hz |

| Maximum Power | 230 W |

| Calibration Medium | Dry air or nitrogen |

| Operating Temperature | 0 °C to 50 °C |

| Storage Temperature | -20 °C to 70 °C |

| Display Readable Distance | 5 m (16 ft) |

| Maximum Sensors Controlled | 10 |

| Maximum Sensors Displayed | 8 |

| Response Time | ≤10 ms |

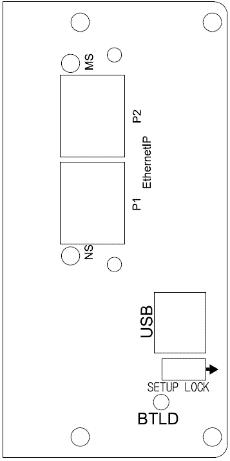

| P1 | EthernetIP RJ45 port 1 |

| P2 | EthernetIP RJ45 port 2 |

| NS | USB communications |

| MS | Module status LED |

| USB | USB communications |

| Setup Lock | Front panel lock switch |

| BTLD | Bootload button |

| Connectors | (2) RJ45 |

| Ports | 10/100 Mbit, half/full duplex |

| DHCP | Enable or disable |

| Class 1 Connections | |

| Connection Type | Point-to-point, multicast |

| Target to Originator Instance ID | 100 |

| Data Size | 40 |

| Originator to Target Instance ID | 150 |

| Data Size | 4 |

| Configuration Instance | 3 |

| Supported Connections | 4 |

| Requested Packet Interval | 1 to 3200 ms |

| Trigger Types | Cyclic, change of state |

| Priorities | Low, high, schedule, urgent |

| Class 3 Connections | |

| Service | 0xE (get), 0x10 (set) |

| Class | 0xA2 |

| Instance | See ADI table |

| Data Value Attribute | 5 |

| Supported Connections | 6 |

| Requested Packet Interval | 100 to 10000 ms |

| Connection Type | Application |

| Priority | Low |

The MX200 has up to eight relay set points. The relays are located on two optional relay modules with four set points each. Individual relay statuses are displayed on the front panel. The heavy-duty relays have an SPDT (1 Form C) contact form and are rated for 24 V DC. They have a maximum current rating of 8 A at 250 V AC or 5 A at 30 V DC.

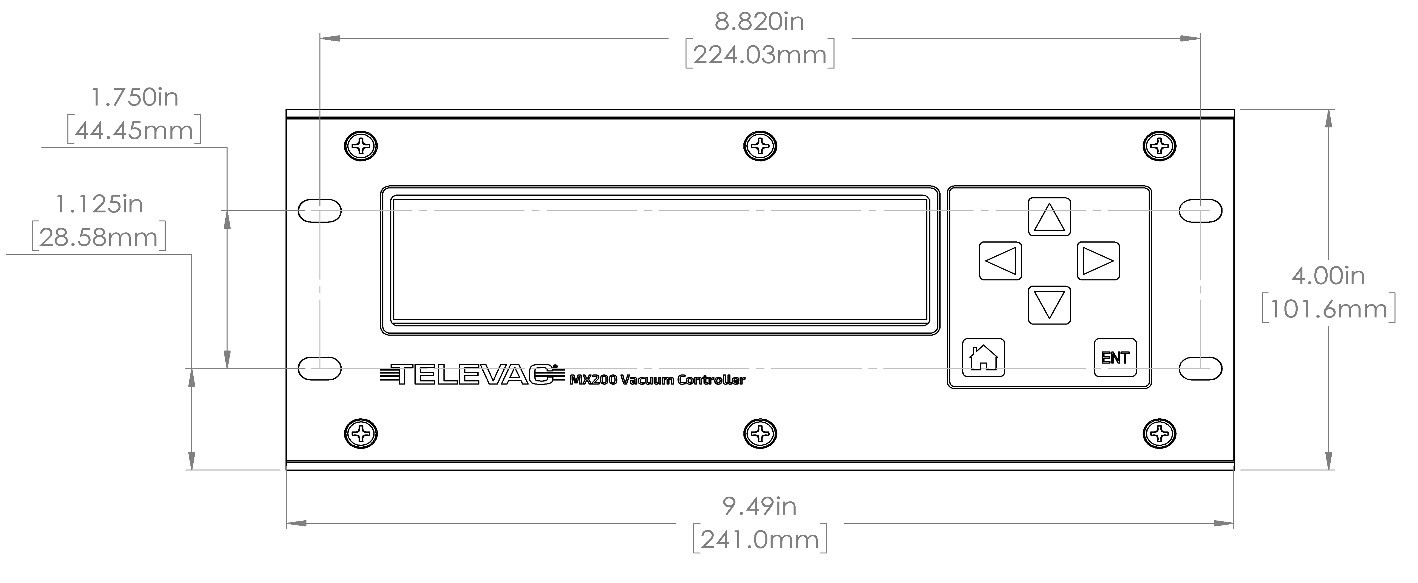

| Housing | Aluminum |

| Electrical Connections | Power cord (IEC 60320 C-13) |

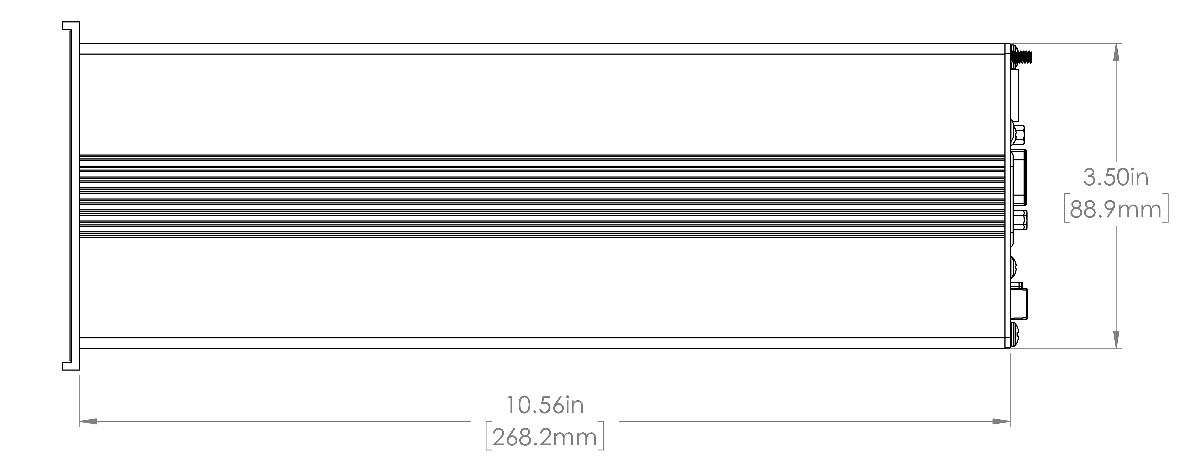

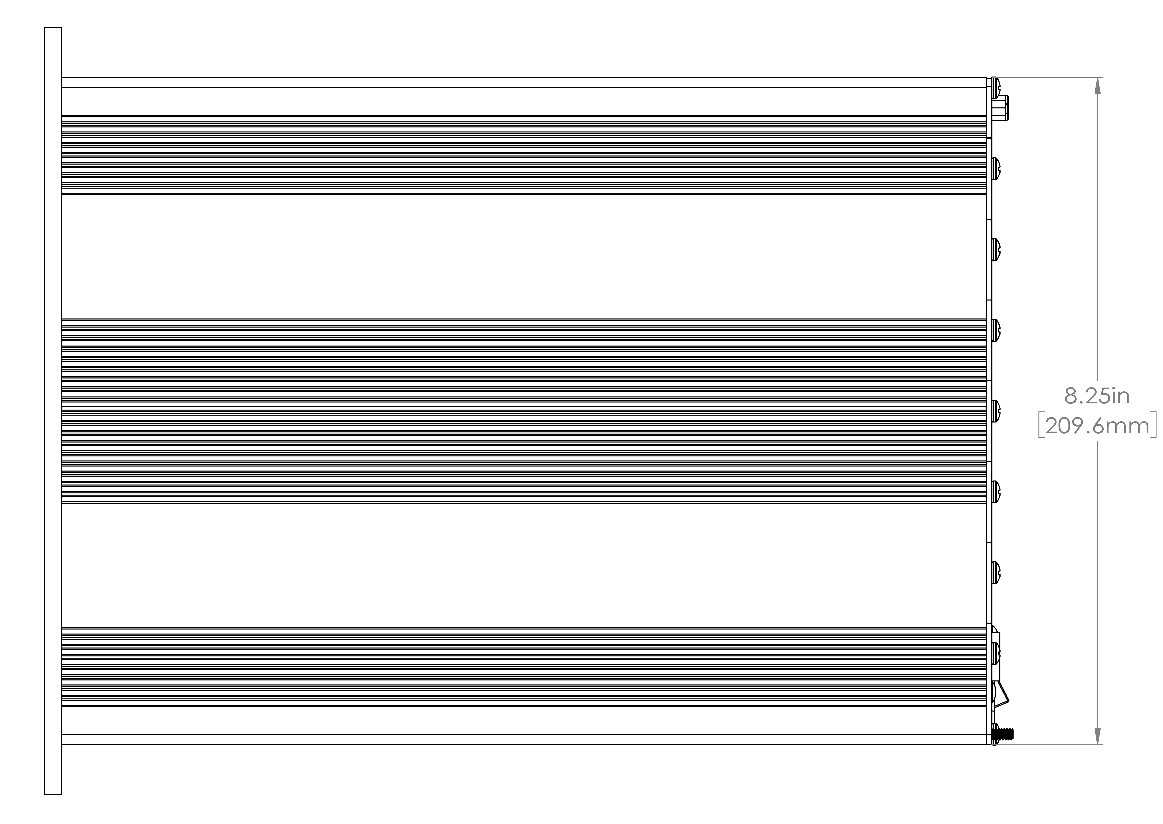

| Weight (Base Unit) | 2.2 kg (5 lbs) |

| Certified to UL 61010-1 |

| CE certified to EN61326-1:2006 |

| Certified to CAN/CSA C22.2 No. 61010-1-12 |

| NRTL certified |

| EAC certified |

| PROFINET certified |

| RoHS compliant |

| REACH compliant |

| ISO 17025 accredited calibration optional |

| NIST traceable calibration optional |

Product Documentation

| MX200 EthernetIP Datasheet |

| MX200 Instruction Manual |

| MX200 EthernetIP EDS File |

| Televac® Vacuum Calibration Tolerances |

3D Model (STEP File)

| MX200 Vacuum Controller STEP File |

Application Notes

Videos

| MX200 Demonstration Video |

Tools

| MX200 Online Order Hub |

| Vacuum Leak Rate Converter |

| Vacuum Measurement Converter |

| Web Serial Terminal |

Case Studies

| Case Study: Argonne National Laboratory |

Articles

| Vacuum Measurement Using Modern Cold Cathode Technology |

Brochures

Download STEP File

| Part Number | Description | STEP File |

| 2-7900-03X | MX200 Vacuum Controller | Download |