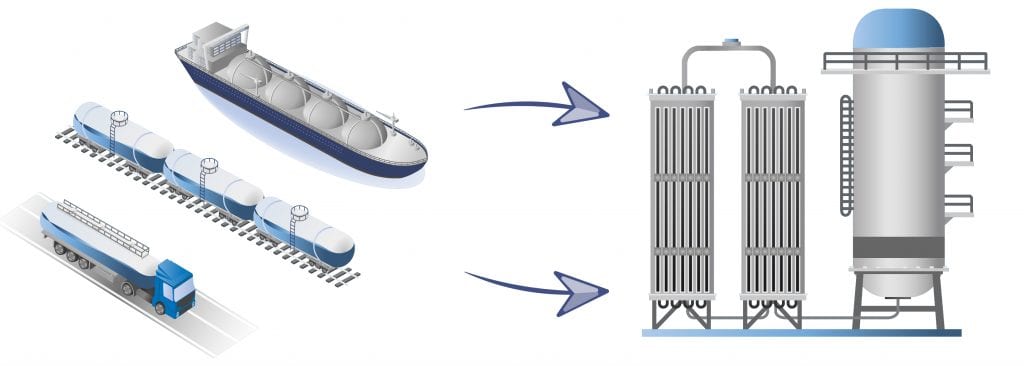

Liquefied natural gas (LNG) is used in a wide range of applications, including space launch, metal processing and vacuum furnaces, medical technology, electronics, water treatment, energy generation, and in the food industry, among many others. Today, industrial gas is delivered to customers in liquefied natural gas (LNG) form at cryogenic temperatures, enabling LNG to be stored on site for later use.

Liquefied natural gas (LNG) is used in a wide range of applications, including space launch, metal processing and vacuum furnaces, medical technology, electronics, water treatment, energy generation, and in the food industry, among many others. Today, industrial gas is delivered to customers in liquefied natural gas (LNG) form at cryogenic temperatures, enabling LNG to be stored on site for later use.

Liquefied Natural Gas (LNG) Tanks and Piping

In order to maintain LNG at extremely low temperatures, LNG is typically stored in double walled tanks or transported in vacuum jacketed LNG piping consisting of two cylindrical vessels, an inner tank (the pressure vessel) and an outer jacket. The air in the space between the inner and outer vessel is known as the annular space, which is evacuated to a specific vacuum level by means of a vacuum pump to create a vacuum and provide vacuum insulation for the LNG.

Vacuum Gauges for LNG

The vacuum insulation is a critical element in a LNG tank, making vacuum gauges, vacuum measurement, and vacuum control a top priority. Televac® offers a wide range of analog vacuum gauges and digital vacuum gauges for liquefied natural gas (LNG) applications including our 2A thermocouple micron vacuum gauge, our 2A VacuMini thermocouple micron vacuum gauge, the robust 2V6 thermocouple micron vacuum gauge, the small and portable Vacuguard™ vacuum controller, and the easy to use MX2A active vacuum gauge. For larger installations of liquefied natural gas (LNG) piping, a controller like the MX200 vacuum controller is often used.

Vacuum Controller Solutions

MX200

1*10-11 Torr to 10,000 Torr

MX200 EthernetIP

1*10-11 Torr to 10,000 Torr

MX200 PROFINET

1*10-11 Torr to 10,000 Torr

VacuGuard™

1*10-3 Torr to 20 Torr

2A Thermocouple (Pirani)

1*10-3 Torr to 20 Torr

2A VacuMini Thermocouple (Pirani)

1*10-3 Torr to 20 Torr

2V6 Thermocouple (Pirani)

1*10-3 Torr to 1 Torr