在 Fredericks 电解倾斜传感器的帮助下,提供世界上最节能的无线监控解决方案。

介紹

美国有超过612,000座桥梁,截至2017年2月,根据美国道路和运输建设者协会的数据,其中近10%的桥梁需要维修或更换。这意味着目前有超过55000座桥梁需要实时监测,以避免像2007年明尼苏达州明尼阿波利斯的桥梁倒塌那样的灾难。

什么是Resensys?

Resensys提供具有成本效益和可扩展性的解决方案,帮助评估这些桥梁和其他公路桥梁的结构稳定性,以便准确定位结构问题,并计划进行必要的维护和修理,以确保桥梁的安全性和使用寿命。

他们的无线结构健康监测解决方案SenSpot™适用于现有桥梁和在建桥梁,其特点是体积小、成本低、易于安装的无线传感器,可测量影响桥梁性能的各种变量。

Resensys公司总裁兼首席技术官Mehdi Khandani博士在马里兰大学进行的研究中诞生,是实时地质结构监测领域的领导者,并提供了最耐用的无线桥梁监测系统,其最低预期寿命为10年。欲了解更多信息,请访问http://www.resensys.com。

挑战

尽管市场上还有其他用于监控基础设施的传感器,但瑞思思设备的与众不同之处在于其超低的功耗,仅使用约4微瓦,约为普通灯泡的1亿倍。这意味着SenSpot传感器只需使用一块½-AA的小电池,就能拥有至少10年的使用寿命。

为了提供如此高效、准确的监控系统,Resensys需要找到一种分辨率高达千分之一度的倾斜传感器,同时还要提供低功耗、耐用性和至少10年的产品寿命。

解决方案

Khandani博士和他的团队彻底评估了各种MEMS和其他电解倾斜传感器,并得出结论,Fredericks单轴窄范围电解倾斜传感器(PN 0703-0711-99)在长期可重复性和分辨率方面明显优于竞争产品。

"Khandani博士说:"从质量上讲,Fredericks的设备比MEMS和竞争对手的电解传感器都要好一个数量级。"在我们的应用中,可重复性是非常重要的,而竞争产品都没有Fredericks的产品做得好。

结果

在Fredericks的电解倾斜传感器的帮助下,Resensys能够提供世界上最节能的无线监测解决方案,帮助保证旅客的安全,在美国和世界各地使用的SenSpot™倾斜装置大约有5000个。

"我们决定使用Fredericks的产品,是因为他们的倾斜传感器具有出色的准确性和耐用性,"Khandani博士补充说。"这种长期和高质量的测量有助于捕捉关键桥梁部件上最小的运动和不稳定性"。

SenSpot™在行动。Patapsco河大桥

2014年春天,马里兰州巴尔的摩附近的I-70 Patapsco河大桥的钢梁和桥墩被发现有裂缝。工程师们发现,无反应的轴承对桥墩和钢梁造成了损害,这导致了该桥在2014年6月关闭。

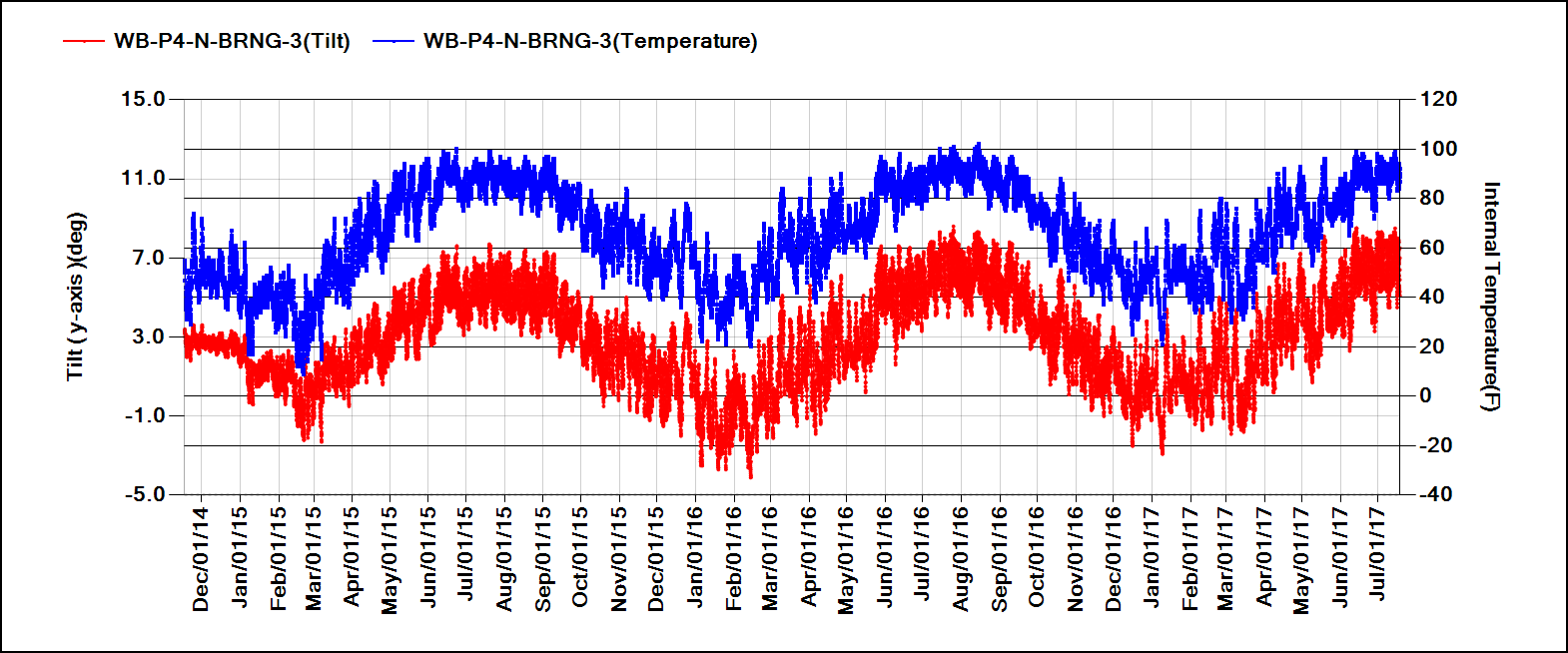

进行了修复,应用了改造,并在2014年7月安装了SenSpot™监测系统,以检测任何进一步的变化。超过40个SenSpot™单元被安装在桥上,包括12个位于桥的摇臂轴承上的倾斜传感器,以监测运动模式并检测无反应或过度反应。此外,6个高分辨率的倾斜传感器被安装在大桥的桥墩上,以监测由低温引起的桥梁摇臂轴承的偏移和旋转。

2014年8月至11月的早期结果发现,两个桥墩上的轴承对温度变化没有反应,另外一个轴承只看到20%的预期运动。然而,到2015年春季收集的数据显示,轴承对强大的改造(加上特别寒冷的冬天)有一个前所未有的反应,到2015年3月,所有的桥墩和各自的轴承都有充分的反应。

Khandani博士指出:"经过四年多的连续监测,我们很高兴SenSpot™传感器中使用的Fredericks装置能以亚弧秒的分辨率对倾斜和倾角进行非常一致、可重复和高质量的测量。"

在向马里兰州公路管理局发出警报之前,Resensys团队与Fredericks的工程师合作,确认了这些数据。在Fredericks,我们采取合作伙伴的方式来处理与客户的关系,客户满意度是我们的首要任务。我们有专门的代表和工程师致力于提供高度响应的服务,我们的客户可以随时与我们的领导团队联系,这在一定程度上得益于我们 "不大不小 "的运作。