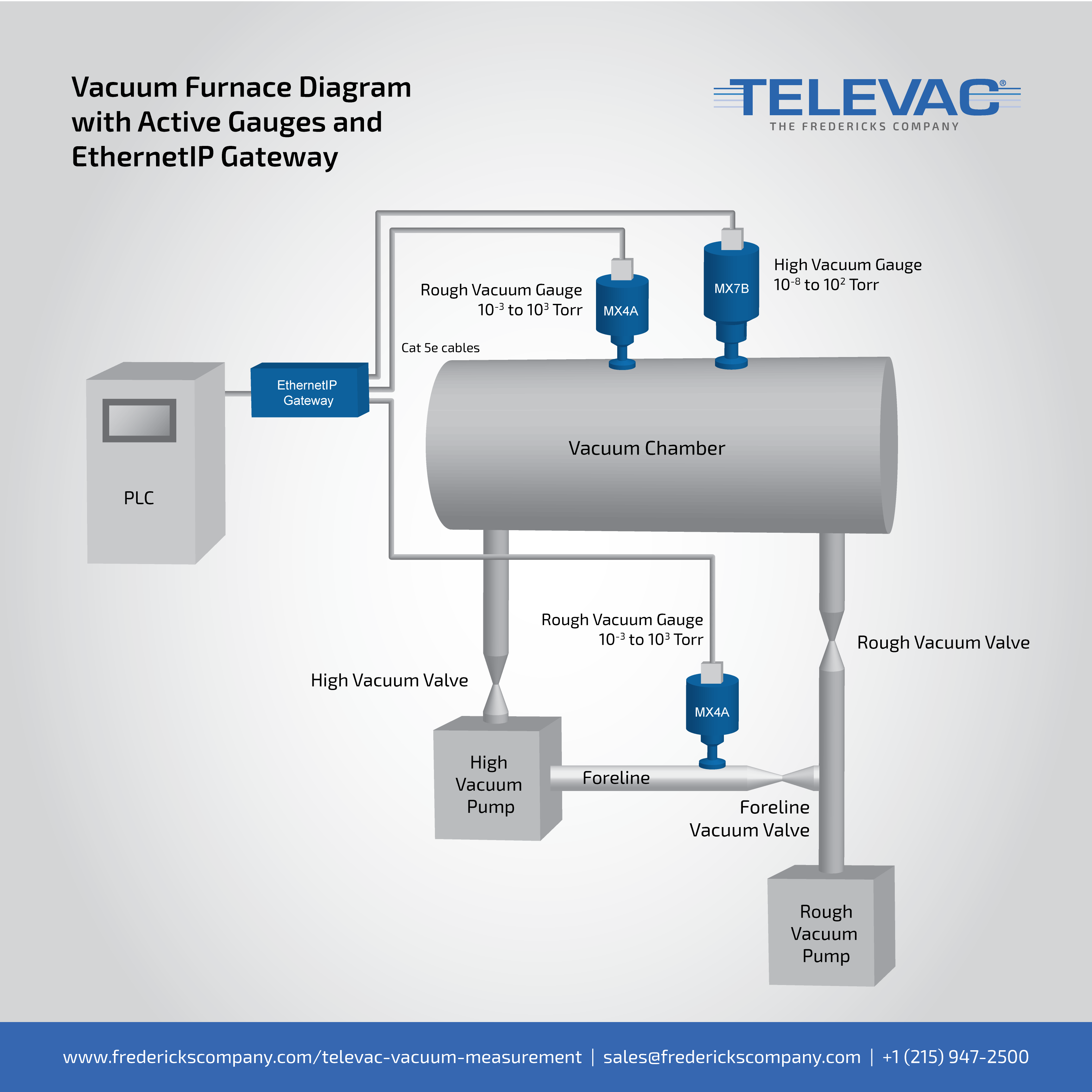

Vacuum furnace and heat treat environments can be problematic for sensitive instrumentation like vacuum gauges and sensors because contamination isn’t just a risk, it’s a given. Since 1935, Televac® has been a preferred supplier of high performance vacuum gauges for the heat treat and vacuum furnace industry because our extensive line of vacuum sensors, active vacuum gauges, and controllers deliver world-class vacuum measurement for demanding environments. Talk to one of our engineers today about our 7B Penning magnetron cold cathode sensor, thermocouple sensors, convection sensors, our MX200 vacuum controller with EthernetIP communications which interfaces directly with Rockwell Automation Allen-Bradley PLCs, or our MX200 vacuum controller with PROFINET communications which interfaces directly with PROFINET-enabled PLCs.

Courtesy of Solar Atmospheres

Cold Cathode Technology for Vacuum Furnaces and Heat Treat

- Penning magnetron vs competing inverted/double inverted magnetron cold cathodes

- Contamination resistant Penning magnetron cold cathode technology

- Cleanable cold cathodes for extended gauge life (bead blasting or abrasive pad cleaning)

- Simple gauge disassembly and cleaning for extended life and lower maintenance costs

Contamination Resistance for Vacuum Furnaces

- Pirani, thermocouple, convection technologies (thermal conductivity gauges)

- Macro vs micro (MEMS) sensors for contamination resistance

- Feedback from customers: MEMS (micro) sensors are more susceptible to contamination, particularly in heat treat/vacuum furnace applications

- Requires more frequent calibration and replacement (additional cost)

- MEMS sensors are often active gauges and include electronics, adding to replacement costs

Digital calibration for Vacuum Furnaces

- Historically all calibration is analog – done with potentiometers (pots)

- Gauges and controllers with display

- Allows calibration at gauge instead of needing multiple people at gauge/display or additional equipment

- Digital calibration – via digital communications

- EthernetIP, PROFINET, RS-232, RS-485, and USB

- Prevents mismatch between HMI and display

- Allows for integration of calibration into PLC HMI

Active Vacuum Gauge Solutions for Nadcap/AMS 2769/Aerospace Certification

To maintain Nadcap accreditation and comply with the requirements outlined in AMS 2769, rough vacuum gauges must be annually (once every year) calibrated to a NIST traceable standard, whereas high vacuum gauges (cold cathodes) require quarterly (once every 3 months) calibration. Active gauges greatly simplify this process by allowing you to return an individual active gauge for calibration without removing any cabling or other equipment from your system.

Vacuum Controller Solutions

MX200

1*10-11 Torr to 10,000 Torr

MX200 EthernetIP

1*10-11 Torr to 10,000 Torr

MX200 PROFINET

1*10-11 Torr to 10,000 Torr

2A Thermocouple (Pirani)

1*10-3 Torr to 20 Torr

4A Convection (Pirani)

1*10-4 Torr to 1000 Torr

7B Penning Magnetron Cold Cathode

1*10-7 Torr to 1*10-3 Torr

Active Vacuum Gauge Solutions

MX2A Thermocouple (Pirani)

1*10-4 Torr to 1000 Torr

MX4A Convection (Pirani)

1*10-4 Torr to 1000 Torr

MX7B Cold Cathode

1*10-8 Torr to 1*10-3 Torr

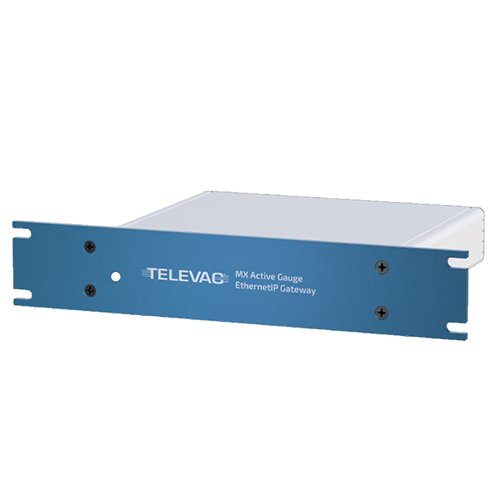

MX Active Gauge EthernetIP Gateway

5*10-11 Torr to 10,000 Torr