E-beam welding is a process where a high energy beam of electrons from an electron gun is accelerated and focused using electric and magnetic fields, and shot at two materials to join them. The kinetic energy of the electrons creates very high heat which melts the two materials together (electrons are particles with a very small mass, 9*10-31 kg or 2*10-30 lbs to be exact). The electron beam requires that the system be under vacuum to maintain the speed and focus of the electrons thus preventing beam dissipation or scattering (without vacuum, the electrons would run into other molecules in the atmosphere like nitrogen, oxygen, and water vapor, among others). This is where Televac® vacuum gauging comes in, to make sure that the system is under sufficient vacuum to operate correctly.

There are two relevant AMS specifications when it comes to E-Beam welding, AMS 2680 and AMS 2681. They call for two different vacuum levels of 1*10-4 Torr and 1*10-3 Torr respectively. Note that these are for aerospace specifications. Depending on the vacuum level and accuracy requirements of the system, there are a few options for Televac vacuum gauging, with important differences noted below.

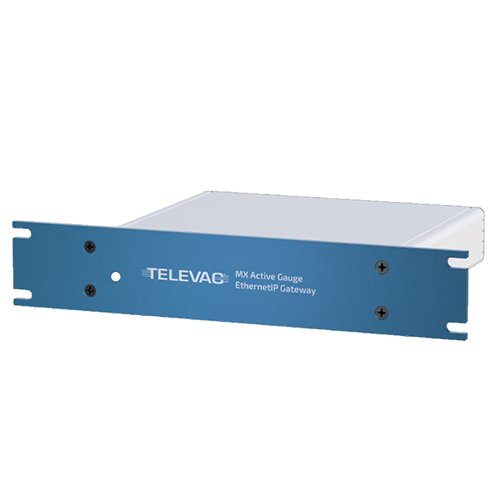

The first option is an active gauge solution. With an active gauge, the control electronics are attached directly to the physical sensor, then there are optional outputs to show the vacuum level including an analog 0 to 10 V output, RS-485 communications, EthernetIP, or PROFINET communications. The active gauges that would be used for E-Beam welding are an MX2A or MX4A (thermocouple vacuum gauges) for measurement from 1000 Torr down to 1*10-3 Torr and then an MX7B (cold cathode vacuum gauge) for measurement from 1*10-3 Torr and deeper vacuum (as low as 1*10-8 Torr).

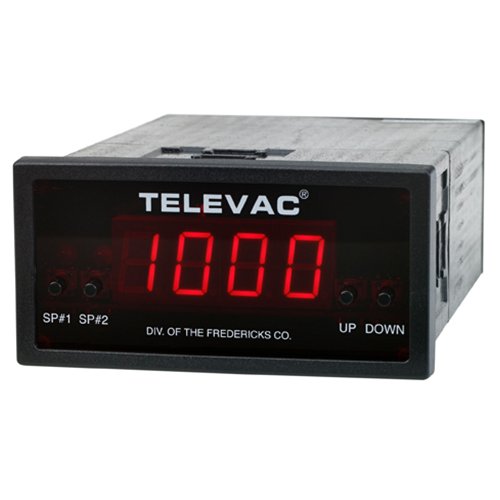

The second option is to separate the control electronics from the physical sensor. This can be ideal if you need or want a remote display somewhere else on your E-Beam welder. The ideal solutions for this are the MV2A and 2A sensor if you only need measurement down to 1*10-3 Torr, or the MX200 with a 2A/4A (again for rough vacuum measurement down to 1*10-3 Torr) combined with a 7B for medium and high vacuum measurement (down to as low as 1*10-7 Torr). Depending on which controller you choose (MV2A or MX200), you’ll have optional outputs of an analog 0 to 5 V signal, an analog 0 to 10 V signal, RS-232 communications, RS-485 communications, or EthernetIP communications.

Confused about the units? Don’t be! Here are some simple conversions from Torr to other common units of measurement (for more conversions, check out our unit converter):

1 Torr = 1.33 mbar

1 Torr = 1 mm Hg

1 Torr = 1.33 * 10-1 kPa

Not sure which product to choose? Chat with us using the window on the bottom right of this screen, give us a call at +1 215 947 2500, or email us at sales@frederickscompany.com!

Note that E-Beam welding can also be done under atmosphere. Because the beam dissipates from hitting the different molecules/gases in the atmosphere, the welds are typically wider, which may not be suitable for certain applications.

Active Vacuum Gauge Solutions

MX2A Thermocouple (Pirani)

1*10-4 Torr to 1000 Torr

MX4A Convection (Pirani)

1*10-4 Torr to 1000 Torr

MX7B Cold Cathode

1*10-8 Torr to 1*10-3 Torr

MX Active Gauge EthernetIP Gateway

5*10-11 Torr to 10,000 Torr

Vacuum Controller Solutions

MX200

1*10-11 Torr to 10,000 Torr

MX200 EthernetIP

1*10-11 Torr to 10,000 Torr

MX200 PROFINET

1*10-11 Torr to 10,000 Torr

MV2A

1*10-3 Torr to 20 Torr

2A Thermocouple (Pirani)

1*10-3 Torr to 20 Torr

4A Convection (Pirani)

1*10-4 Torr to 1000 Torr

7B Penning Magnetron Cold Cathode

1*10-7 Torr to 1*10-3 Torr