How Do Freeze Dryers Work?

Food or other materials are placed in a vacuum tight chamber which is cooled to between -30 °F to -50 °F (-34 °C to -46 °C), below the triple point of the liquids you’re trying to remove (usually the primary liquid you’re trying to remove is water). The material is given time to freeze, then a vacuum pump creates a vacuum (reduces the pressure) in the chamber, effectively reducing the temperature where liquids or solids will transition into a gas. Once the material is frozen, the chamber is gradually warmed (still under vacuum), which turns the frozen liquid into a vapor or gas through sublimation (when a solid turns directly into a gas, skipping the liquid stage, hence the importance of the triple point). The triple point for water is 0.01 °C and 4.58 Torr.

The process removes all liquid from the material, then the chamber is returned to atmospheric pressure by reintroduction of a dry gas like nitrogen. The material must then be packaged inappropriately sealed packaging to prevent the reintroduction of any liquids. Throughout this whole process, the physical form of the material is kept intact, and the residual moisture still left in the material is usually in the range of 1% to 5%.

Vacuum Gauges for Freeze Dryers

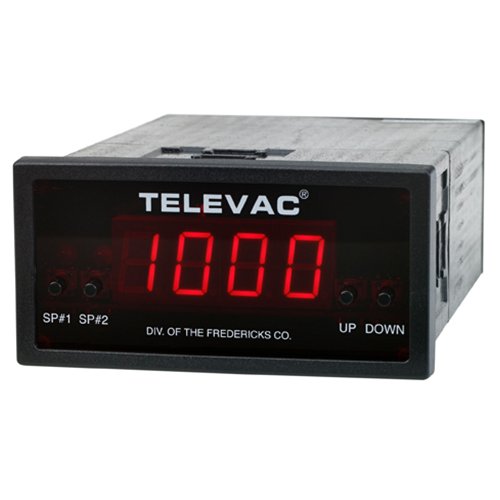

Most freeze dryers operate in rough vacuum (10-3 Torr up to 760 Torr or atmosphere) due to the triple point pressure of water at 4.58 Torr, so any of our rough vacuum gauges are an excellent fit for freeze drying applications. For a standalone active gauge, check out the MX2A thermocouple or MX4A convection active gauges. If you’d prefer a rack mountable controller, check out the MV2A controller and the 2A passive thermocouple vacuum gauge.

Not sure which product to choose? Chat with us using the window on the bottom right of this screen, give us a call at +1 215 947 2500, or email us at sales@frederickscompany.com!

Active Vacuum Gauge Solutions

MX2A Thermocouple (Pirani)

1*10-4 Torr up to 1000 Torr

MX4A Convection (Pirani)

1*10-4 Torr up to 1000 Torr